Login

- Optimised hydraulics for high efficiency

- Reduced power consumption

- High-efficiency motors

- TP pumps are fitted with high-efficiency motors

- High-efficiency motors provide reduced energy consumption

- 2-pole and 4-pole TP pumps from 0.75 kW to 375 kW have IE3 motors (By March 2012)

- Top-pull-out design

- Easy dismantling for service

- In-line design

- Unlike end-suction pumps, in-line pumps allow the use of straight pipework, which often results in reductions in installation cost and amount of space occupied

- Hydraulically and mechanically balanced impeller (Series 300 and 400)

- The impeller is hydraulically and mechanically balanced to increase the life of motor bearings and shaft seals

- Pump housing and pump head/motor stool are electro-coated

- Improved corrosion resistance

- TPE, TPED – pumps with built-in frequency converter

- Reduced power consumption

- TPE and TPED motors are based on IE3 motors (except 18.5, 4-pole).

Overview

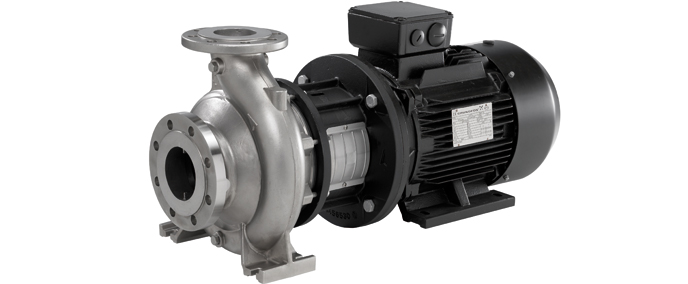

Grundfos TP and TPE vertical in-line volute pumps are used in a variety of applications. The pumps are all single-stage, in-line centrifugal volute pumps with standard motors and mechanical shaft seals. The pumps are of the close-coupled type, i.e. pump and motor are separate units. Consequently, the pumps are less sensitive to impurities in the pumped liquid than similar pumps of the canned rotor type.

Two different models of vertical in-line volute pumps are available. Please note that there are a number of specific product variants available for each model. Detailed information on these variants can be found in Grundfos WebCAPS.

The pumps are all single-stage, in-line centrifugal volute pumps with standard motors and mechanical shaft seals. The pumps are of the close-coupled type, i.e. pump and motor are separate units. Consequently, the pumps are less sensitive to impurities in the pumped liquid than similar pumps of the canned rotor type.

Two different models of vertical in-line volute pumps are available. Please note that there are a number of specific product variants available for each model. Detailed information on these variants can be found in Grundfos WebCAPS.

TP pump

This pump model is notable for its high levels of reliability and efficiency. Quiet, highly-efficient IE3 motors are standard components. All TP pumps are electro-coated to ensure high corrosion resistance.TPE pump

The main difference between TP and TPE pumps is the motor. TPE motors have a built-in frequency converter, allowing different control methods to be employed. TPE pumps offer benefits with respect to energy savings and increased comfort.Applications

These vertical in-line volute pumps are used in commercial buildings for air conditioning and heating applications.The pumps are all single-stage, in-line centrifugal volute pumps with standard motors and mechanical shaft seals. The pumps are of the close-coupled type, i.e. pump and motor are separate units. Consequently, the pumps are less sensitive to impurities in the pumped liquid than similar pumps of the canned rotor type.

Features and benefits

Buy now

TP, TPE

0

Quantity: 1

CUSTOMER INFORMATION

SHIPPING ADDRESS

PAYMENTS

YOUR ORDER INFORMATION

TP, TPE

0

Quantity: 1

Subtotal

CUSTOMER INFORMATION

- Full name:

- Phone:

- Email:

SHIPPING ADDRESS

- Address:

- Country / district:

- Province / city:

- Shipping costs:

- Note:

PAYMENTS